Choosing the right printing method for customizing t-shirts is crucial, as it significantly impacts the quality, durability, and visual appeal of the final product.

There are various popular t-shirt printing techniques, each offering its own set of advantages and disadvantages.

This blog aims to delve into the most common printing methods, providing the information needed to make well-informed decisions for your upcoming custom apparel project.

Overview of T-Shirt Printing Methods

- Screen Printing

- Direct to Garment (DTG) Printing

- Heat Transfer Printing

- Sublimation Printing

- Vinyl Printing

- Embroidery

- Direct-to-Film (DTF) Printing

- Puff Printing

T-Shirt Printing Methods Comparison

| Printing Method | Best For | Durability | Setup Time | Fabric Compatibility | Cost |

|---|---|---|---|---|---|

| Screen Printing | Bulk, bold designs | Very High | High | Most fabrics | Low for bulk |

| DTG Printing | Small runs, detailed designs | Moderate | Low | 100% Cotton | Moderate |

| DTF Printing | All-purpose, colorful designs | High | Moderate | Almost all fabrics | Moderate |

| Heat Transfer | Photos, small batches | Low | Low | Wide range | Low |

| Dye Sublimation | All-over prints, polyester only | Very High | Moderate | Polyester only | High |

| Puff Printing | 3D effects, bold logos | High | High | Cotton, blends | Moderate to High |

| HTV | Personalized designs | High | High | Wide range | Low |

| Embroidery | Logos, uniforms, premium items | Very High | High | Heavier fabrics | High |

1. Screen Printing

What is screen printing?

Screen printing, also known as silkscreen printing, is one of the oldest and most reliable methods of t-shirt customization. It uses a stencil and a fine mesh screen to apply layers of ink onto the fabric.

Each color in the design requires a separate screen, making it ideal for bold, solid-color designs. With its vibrant and durable results, screen printing remains a favorite for bulk production and promotional t-shirt orders.

Best Applications of

Bulk Orders: Ideal for large quantities due to reduced per-unit cost.

Bold, Simple Designs: Works best for designs with a few colors and solid areas.

Special Effects: Great for achieving textured prints like puff, glitter, or metallic effects.

Promotional Merchandise: Perfect for company logos or event branding on cotton or polyester fabrics.

Pro:

- Durability: Long-lasting prints that withstand frequent washing.

- Cost-Effective for Bulk: Economical for large orders.

- Versatile: Works on various fabrics and can achieve special effects.

Cons:

- Setup Costs: High initial setup makes it less practical for small batches.

- Color Limitations: Adding more colors increases complexity and expense.

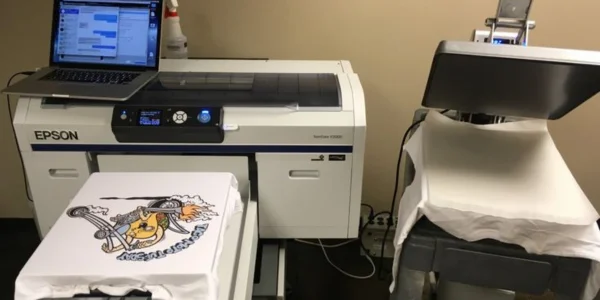

2. Direct-to-Garment (DTG) Printing

What is DTG printing?

Direct-to-garment (DTG) printing is a modern method that leverages inkjet technology to print directly on fabric using water-based inks. One of the standout features of DTG is that it doesn’t require stencils, which sets it apart from traditional screen printing.

This makes it an ideal option for intricate designs that involve multiple colors or even photorealistic images. If you want to create detailed graphics with gradient effects, DTG is a fantastic choice, especially for small batches or personalized items.

Best Applications:

Small-Scale Runs: Ideal for one-off prints, prototypes, or personalized orders.

Detailed Designs: Excellent for photorealistic images, intricate artwork, and gradients.

Custom Branding: Suitable for low-volume branding projects like team t-shirts or personalized gifts.

E-commerce: Favored by print-on-demand businesses for quick and high-quality results.

Pros:

- Detail-Oriented: Ideal for intricate and colorful designs.

- Soft Feel: The ink absorbs into the fabric.

- Small Batch Friendly: Minimal setup for one-off or small orders.

Cons:

- Durability: Prints may fade over time.

- Material Constraints: Best suited for 100% cotton fabrics.

3. Direct-to-Film (DTF) Printing

What is DTF printing?

Direct-to-Film (DTF) printing is a versatile method that transfers a printed design onto a special film, which is then heat-pressed onto fabric. DTF is gaining popularity for its ability to print on almost any material.

Best Applications:

All-Purpose Use: Works well on t-shirts, hoodies, bags, and caps.

Custom Printing: Suitable for detailed and colorful designs.

E-commerce: Great for small-scale print-on-demand services.

Pros:

- Versatility: Works on cotton, polyester, blends, and more.

- High Durability: Prints are soft yet long-lasting, resisting cracking or peeling.

- Full Color Range: Excellent for detailed and vibrant designs.

Cons:

- Setup Costs: Requires specific printers and film materials.

- Environmental Concerns: Inks and adhesives can be less eco-friendly.

4. Heat Transfer Printing

What is heat transfer printing?

Heat transfer printing is a method where you transfer designs from specialized transfer paper onto fabric using heat and pressure. This technique is known for producing high-resolution prints with vivid colors, making it a great choice for detailed graphics and photographic designs.

It’s especially useful for small production runs or unique, one-off projects since it has a quick setup time and doesn’t require much equipment. If you’re looking to create custom apparel or unique GSM’s of fabric designs, this method could be a perfect fit for you.

Best Applications:

Photographic Prints: Great for t-shirts featuring detailed images or logos.

On-Demand Printing: Used for personalized gifts, custom event t-shirts, or short-run promotional items.

Wide Fabric Range: Effective on materials like cotton, polyester, and blends.

Fashion Lines: Ideal for small-scale boutique collections requiring diverse designs.

Pros:

- Highly Detailed: Excellent for high-resolution designs and photos.

- Versatile: Works on various fabric types.

- Minimal Setup: Suitable for on-demand printing.

Cons:

- Durability Concerns: Prints may peel or crack.

- Heavy Feel: Can feel less breathable compared to other methods.

- Dark Fabric Limitations: May require extra steps for darker fabrics.

5. Dye Sublimation

What is sublimation printing?

Dye sublimation is a printing technique that uses heat to transfer dye onto materials, primarily polyester fabrics. In this process, the dye turns into gas and bonds with the fibers, resulting in bright, all-over prints that are soft and lightweight.

This method permanently embeds the design into the fabric, making it highly durable. While it’s ideal for polyester and often used on light-colored materials, its exceptional print quality makes it a popular choice for fashion and activewear.

Best Applications:

All-Over Printing: Perfect for full-coverage designs like custom jerseys or vibrant patterns.

Sportswear: Ideal for high-performance polyester apparel, including jerseys and tracksuits.

Artistic Prints: Great for bold, colorful designs that require durability and vibrancy.

Home Decor: Frequently used for custom polyester items like cushions and curtains.

Pros:

- Vivid Results: Produces bright and fade-resistant designs.

- Durability: The dye becomes part of the fabric.

- All-Over Printing: Seamless designs across the entire shirt.

Cons:

- Fabric Limitation: Only works on polyester and light-colored fabrics.

- Higher Costs: Equipment and material expenses can be significant.

- Niche Appeal: There is less demand for polyester garments.

6. Puff Printing

What is sublimation printing?

Puff printing is a special effect technique often combined with screen printing. A puff additive is mixed with ink, causing the design to rise and create a 3D texture when heat is applied.

Best Applications:

Logo Emphasis: Great for highlighting brand logos.

Limited Edition Lines: Adds exclusivity to special collections.

Pros:

- Unique Finish: Creates a raised, tactile design.

- Stylish Appeal: Adds depth to logos and typography.

- Durable: Maintains the 3D effect even after washing.

Cons:

- Limited Detail: Not suitable for intricate designs.

- Material Compatibility: Works best on cotton or cotton blends.

7. Heat Transfer Vinyl (HTV) Printing

What is vinyl printing?

HTV printing, or heat transfer vinyl printing, is a method where you cut out shapes or designs from a special type of vinyl. You then use heat and pressure to stick these designs onto the fabric.

It’s a great way to create custom looks because you can choose from many colors and finishes.

Best Applications:

Small Runs: Ideal for small quantities and personalized items.

Simple Designs: Works best for designs with fewer colors.

Fashion Apparel: Suitable for custom or boutique clothing collections.

Pros:

- Versatile: Available in many colors and finishes.

- Durable: Vinyl is generally durable and withstands washing well.

Cons:

- Limited Detail: Not suitable for intricate designs with fine details.

- Feel: The vinyl can add a noticeable layer to the fabric.

8. Embroidery

What is embroidery?

Embroidery is the process of stitching designs directly onto fabric using threads. Known for its classic, textured, and premium look, it’s widely used for branding purposes. While it’s not suitable for intricate designs, embroidery is valued for its durability and high-end appearance, making it a favorite for corporate wear and uniforms.

Best Applications:

- Corporate Wear: Ideal for embroidered logos on polo shirts, caps, and jackets.

- Uniforms: Commonly used for durable, long-lasting designs on workwear.

- Premium Branding: Suitable for businesses looking to create a professional and upscale image.

- Accessories: Perfect for hats, tote bags, and backpacks.

Pros:

- Professional Look: Adds a premium, textured appearance.

- Long-Lasting: Withstands washing and wear.

- High Value: Enhances perceived product quality.

Cons:

- Expensive: Higher production costs.

- Limited Detail: Not ideal for intricate patterns.

- Fabric Restrictions: Can distort lightweight fabrics.

Frequently Asked Questions about Printing Types

When it comes to bulk orders, screen printing is often the top choice. It’s cost-effective for larger quantities because the setup costs are spread over the volume of shirts printed.

However, if your design has multiple colors or gradients, DTF (Direct-to-Film) printing can be a versatile alternative as it doesn’t require separate screens for each color.

Choosing the right printing method depends on your design’s complexity, the quantity needed, and the type of fabric.

- For intricate designs with many colors: DTG (Direct-to-Garment) or DTF printing is ideal.

- For bold, simple designs: Go with screen printing, especially for bulk.

- For polyester or all-over prints: Opt for dye sublimation.

- For a premium 3D look: Puff printing works best.

Consider your fabric type too—DTG is perfect for cotton, while sublimation works only on polyester. Balance your design and budget to make the best decision

- Durability depends on the method and care. Screen printing is widely recognized for its longevity, especially on cotton fabrics, as the ink deeply bonds with the material.

- Dye sublimation also offers exceptional durability on polyester fabrics since the design becomes part of the fabric itself.

- DTF printing provides decent durability and is versatile across fabric types,

- Versatility: It works on almost all fabrics, unlike DTG, which is limited to cotton.

- Vibrant Colors: DTF can achieve sharp, vivid prints with less effort compared to DTG or screen printing.

- No Minimums: Ideal for short runs or single pieces.

However, DTG excels in high-resolution photo-like designs on cotton and feels softer. Screen printing remains unbeatable for bulk orders with bold, long-lasting prints. DTF is a flexible middle ground, perfect for smaller, colorful, multi-fabric projects.

For polyester fabrics, dye sublimation is the top choice. It infuses the design directly into the fabric, ensuring a vibrant, long-lasting print that doesn’t fade or crack over time.

If you’re looking for more versatility, DTF printing also works well on polyester and offers flexibility in design complexity and small-batch printing.

Avoid methods like DTG, as they aren’t as effective on polyester due to ink compatibility issues.